News

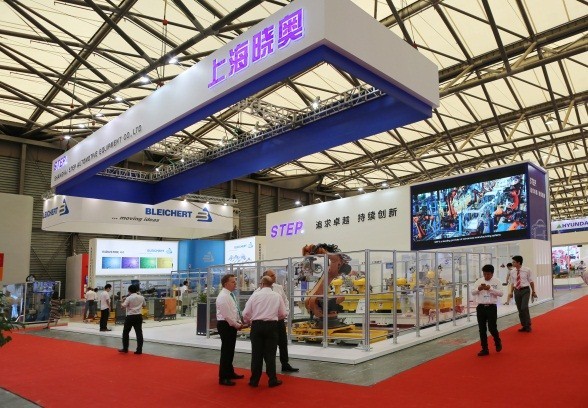

STEP appeared at Shanghai International Automobile Manufacturing Technology, Equipment and Materials Exhibition

Time:

2016-08-29 13:12

From August 24-26, the 12th International Automobile Manufacturing Technology, Equipment and Materials Exhibition was held in Shanghai New International Expo Center. Shanghai STEP Xiangrong Automobile Industry Equipment Co., Ltd. participated in E2-C16 in Hall E2. During the period, STEP conducted in-depth exchanges and communications with industry professionals and partners from home and abroad, and showed everyone a history of STEP with continuous innovation.

Shanghai STEP is a manufacturing system solution provider with rich experience in the design and manufacturing of automotive body-in-white equipment and system integration. Its main customers are major domestic and foreign automobile manufacturers. At this exhibition, Shanghai STEP demonstrated a number of solutions for high-speed rolling machines and positioning trolleys, flexible automatic body positioning systems, robotic riveting systems, robotic sliding rail systems, and automotive flexible production.

High-speed rolling machine and positioning trolley system

High-speed roller bed

• The transmission speed is fast, the transmission time between stations (6m) is 5-6 seconds, and the lifting time is 1.5 seconds

• High transmission accuracy, equipped with code rule closed loop control, high reliability and high precision

• Configure vehicle recognition system

Positioning trolley

• Trolley structure is sturdy and durable

• The trolley is clamped by a pin cylinder, mechanically self-locking, and the clamping force and holding force are reliable

• Adopting windmill type switching structure, fast switching speed and high precision

Model switching mechanism

• Simple structure, high precision, stability and reliability.

Flexible automatic body positioning system

STEP's flexible automated body positioning system adapts to flexible switching production schemes for multiple models, which can effectively simplify tooling design and reduce the investment in secondary tooling. Modular design, easy to replace and combine.

Technical characteristics

• Developed based on STEP robot control technology to realize synchronous movement

• It is convenient to get multiple combinations according to actual needs

Optional function

• Can work with robots

• Can provide automatic zero patrol system

• Can provide automatic lubrication system

Robot slide system

The external axis track of Xiao'ao robot cooperates with the new Shida robot control technology, which can be used in standard spot welding, handling, gluing and other occasions.

Technical characteristics

• Modular design, compact structure, easy to plan and arrange

• Integral frame, reducing installation and debugging time

• Good positioning repeatability

• It can be used with robots of multiple brands

Optional function

• Can provide automatic zero patrol system

• Can provide automatic lubrication system

Robot riveting system

STEP's professional riveting laboratory and riveting technical team can carry out theoretical analysis of the feasibility of riveting; verify the theoretical data through riveting tests; provide the best integrated solution for rivets, riveting and other related equipment.

System process: The robot carries the riveting gun to automatically riveting, the riveting gun presses the riveted plate, the rivet is pressed and embedded by the anchor rod, penetrates the upper plate, and expands into the next layer, and then the rivet expands with the plate and fills the riveting die and rivet. The legs are turned around to form buttons, thereby completing the connection of the upper and lower plates.

Device Configuration

• Robot system

• Point servo riveting system

• Automatic nail feeding system

Technical characteristics

• High connection repeatability

• Protect the coating of riveting materials and improve corrosion resistance

• Adapt to multi-layer and various types of plates

• No smoke, no sparks, no harmful gases

• High strength and long life

• Convenient for visual inspection

Next